- Industriestr. 20; D-94330 Salching

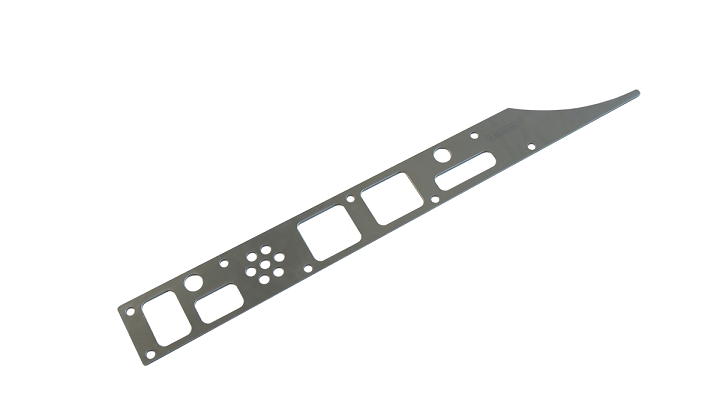

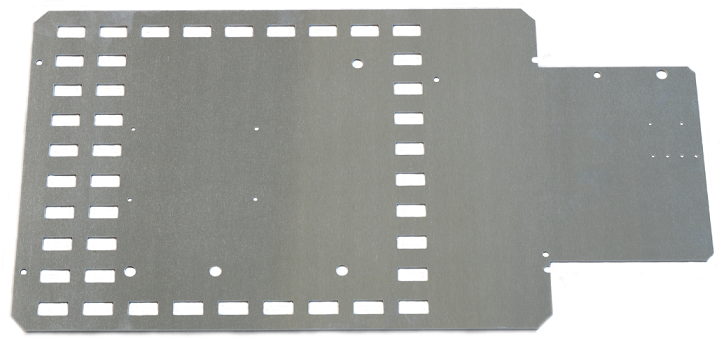

Laser cutting

- We are experts in the area of laser and laser punching processing. Thanks to our state-of-the-art laser machines, we provide our customers with first-class products manufactured according to individual specifications. The manufacturing documents and dimensional drawings are provided by our customers.

- Our laser systems cut almost any contour quickly and flexibly, even filigree and complicated shapes do not pose a problem. With our modern laser cutting systems, steel, stainless steel, aluminum and special materials can be cut precisely and with high quality.

- We can produce small and large quantities quickly, cost-effectively and with consistent precision. The clean cuts make further processing easy. Thanks to full automation and the use of the latest laser cutting and punching technology, we can offer special contract manufacturing options.

Advantages

- Small quantity as well as large quantity production (for large series)

- No power impact on your product

- Contactless machining process

- No damage to the surfaces

- High cutting speed (more than 10 m/min possible)

- Economically sensible for single-item production and large series

- Possible to cut very small contours

- Rework-free cut edges (depending on material)

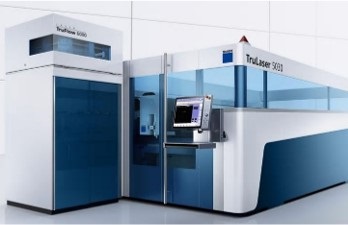

2x TruLaser 5030 (6 KW)

1x TruLaser 5030 fiber (5 KW)

1x TruLaser 5040 (6 KW)

1x TruLaser 5030 fiber (6 KW)

1x StanzLaser Tru Matic 7000 (4 KW)

LASER CUTTING TECHNOLOGY

Using the latest technology Technology: CO2 / fiber laser Power: up to 7,000 W Max. size: 4,000 x 2,000 mm Max. thicknesses:

- -25 mm in steel

- -30 mm in stainless steel

- -15 mm in aluminium

Cutting accuracy up to +/- 0,1 mm

LASER PUNCHING TECHNOLOGY

Range: 3,120 x 1,660 mm Power: 4,000 W Max. punching force: 220 KN Max. punching diameter:76.2 mm Cutting accuracy up to +/- 0,1 mm