- Industriestr. 20; D-94330 Salching

Deburring

- When sheet metal is produced using the laser cutting method, burrs and slag occur on the laser entry and laser exit sides due to thermal influences.

- During the mechanical processing of milled and turned parts, burrs occur on the work piece edges due to material displacement; this is similar when punching work pieces.

We can remove burrs by using the following methods:

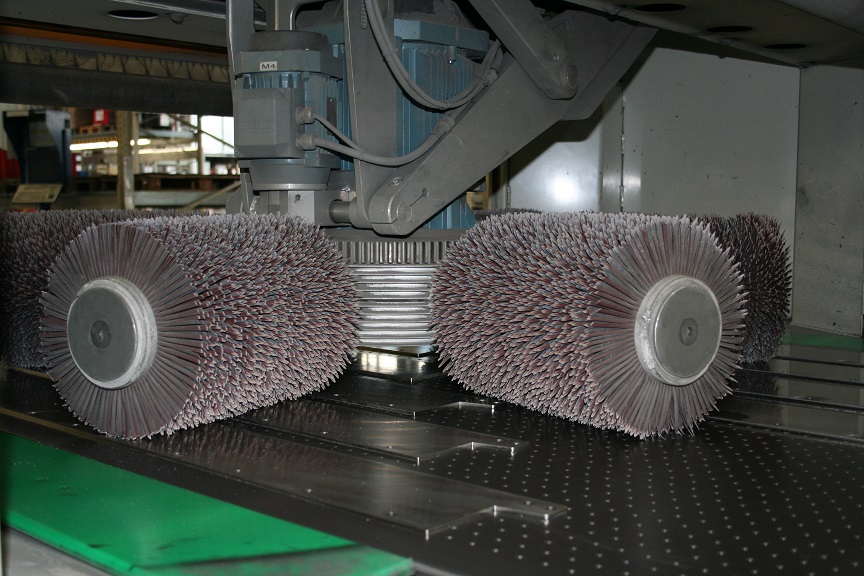

- Grinding by means of wet grinding and dry grinding machines equipped with deburring rollers, abrasive cloth and deburring brushes with a wide range of grain sizes

- Edge breaking by means of dry sanding machines equipped with lamellar rollers and a wide range of grain sizes and corundums

- Grinding using the slide grinding process

- Manual sanding with hand-held sanding machines such as angle sanders and air sanders

- Our abrasive belts and abrasives have different grain sizes and can be customized to meet all needs

Lissmac grinding machine SBM-L G 152

- Deburring and edge rounding of work pieces up to 50 mm sheet thickness

- Removal of spatter on the sheet metal surface

- Deburring of the work pieces on both sides saves cost-intensive turning of the often heavy work pieces or machining the parts twice

- Simultaneous deburring and edge rounding of the inner and outer contours

- Dry machining

- Simple, intuitive operation (Siemens 7)

- The machining units can be adjusted individually electrically or can be switched on and off

- Highest productivity with constant machining quality

- The transverse machining principle ensures optimum tool utilization over the entire working width

- Quick and easy tool change within a few minutes

- Modular, compact construction in modern machine design - little space required

- Improved working environment - reduction of dust, dirt and noise levels

Deburring and edge rounding on both sides in a single cycle

2 Fladder Gyro

- Continuous deburring with grinding flaps for rounding edges

- Processing width up to 1,600 mm

- Dry grinding

2x Ernst wet grinding machine

- Continuous deburring with grinding rollers and stainless steel brushes / wide belt, fleece flaps and flap brushes

- Processing width up to 1,540 mm

- Thickness up to 60 mm

- Wet grinding