- Industriestr. 20; D-94330 Salching

Blasting

- Surface finishing of stainless steel through blasting

- Ceramic blasting creates structured and satin surfaces on your work pieces.

- As a result, you meet high requirements - in terms of function as well as aesthetics.

- We blast in blast cabinets by hand and with continuous belt blasting machines using a wide variety of blasting media.

- Blasting for optical applications (decorative blasting): You get silky-matt, satin surfaces in various degrees of gloss. By using different sizes of abrasives (grain size or granulation) and different pressures, different surfaces can be created during blasting. For example, glass bead blasting produces silky-matt glossy surfaces, while blasting media made of stainless steel corundum create more matte surfaces in the continuous belt blasting machine.

Advantages of blasting

- Uniform degree of gloss

- Corrosion protection and removal of discoloration

- Surface finish can be optimally adjusted to customer requirements

- High throughput when using a continuous belt blasting machine

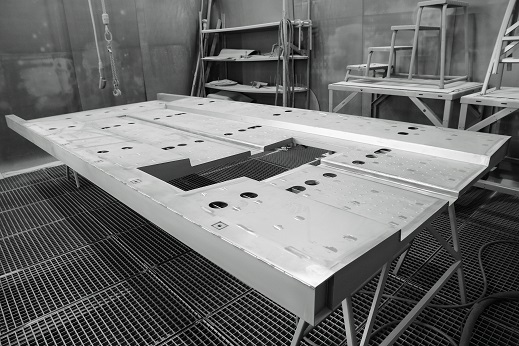

Blasting house

- 6x4x4 m

- 2 sand blasting cabins

- Use of ceramic pearls

Continuous belt blasting machine

- Rösler continuous belt blasting machine RBD 800

- Max. part size 750 mm x 80 mm